ΠΕΡΙΕΧΟΜΕΝΑ

ToggleThe technologies that can bring energy savings

Modern societies and economies are still today highly dependent on the overconsumption of the planet's natural resources. Despite intensive efforts to transition to 'green' technologies that will lead to sustainable development in societies, the new emerging conditions, due to the ever worsening energy crisis and climate change, are shaping a new scenario, signalling in all directions that faster and more effective action needs to be taken.

The need for immediate action becomes even more urgent, if we take into account that in recent years in the Greek territory hundreds of families have fallen into financial and energy poverty, while we have an ever-increasing consumption of energy in the building sector to meet energy needs. Therefore, all those actions and policies should be aimed at the proper use of natural resources at a rate lower than the rate at which they are renewed, always with the main objective of protecting the environment, reducing emissions of various pollutants, the well-being of citizens, the development of new green technologies and the preservation of biodiversity.

According to official studies, the building sector, of all types, is responsible for over 41% of total annual energy consumption and 36% of greenhouse gas emissions in Europe. For Greece, the figures are proportionally even higher! Of the 41% figure, almost 85% relates to the energy consumption required to meet the thermal needs of buildings and the production of Domestic Hot Water (DHW). In this light, it is immediately clear that the energy upgrade of heating and DHW production systems, in the context of the broader effort to increase the energy efficiency of buildings and reduce greenhouse gas emissions, can bring about significant energy savings. In view of the continuous increase in energy costs, the need for energy upgrading becomes even more urgent.

The European Union, realising that the potential for energy savings in buildings is huge and knowing that this will be achieved mainly through increased energy efficiency, has adopted a series of directives where energy reduction and the use of renewable energy sources (RES) will be at the forefront of its policy. Thus, through various Community directives (such as 2009/125/EC-Ecodesign), it is leading producers and final consumers towards systems and products that will replace conventional energy-intensive installations and incorporate new technologies that consume less energy, emit fewer pollutants and use environmentally friendly materials.

In the following, the most important technologies that are currently readily available to end consumers and which can bring huge energy savings are presented. However, it is very important to understand that comparisons between technologies are not valid, as they have all been developed to offer solutions. There are no 'good' and 'bad' technologies but technologies that address different applications. The criterion of choice, regardless of which fuel is more expensive or cheaper at a given time, should therefore always be which technology is best suited to the application and has the lowest possible operating costs over time.. Interventions related to the building such as thermal insulation of the masonry or changing the windows are equally imperative as they reduce heat losses and contribute to further fuel savings. However, interventions to upgrade the heating system are demonstrably more cost-effective and easier to implement, particularly in the case of existing buildings, and are the most immediately depreciable investments.

Air-to-water & Geothermal heat pumps

Heat pumps are undoubtedly the most modern and advanced technology available for heating and cooling of a building. This is because their main characteristic is the high degree of efficiency (the ratio of the energy produced to the energy consumed to produce the project) which can even reach and the 5, depending on the type of heat pump (air-cooled or geothermal) and the type of application.

Heat pumps are systems that have the ability to "absorb" heat from the environment, with the help of a cooling fluid that has the ability to evaporate at low temperatures, and through the cooling cycle to deliver it to the interior. The exact opposite of course happens during the cooling operation. The medium used to deliver the heat to the building is water, so the combination of the heat pump with all water systems is possible (underfloor and wall-ceiling heating, fancoils, radiators, convectors, etc.). The main categories of heat pumps are two: air-cooled and water-cooled or more commonly known as geothermal. Air-cooled ones, in order to produce work, exchange energy with the ambient air, while geothermal ones exchange energy with the subsoil through a secondary circuit where the medium is water.

The most important characteristic of all heat pumps, which must always be taken into account during the design phase of a system, is that their efficiency is inextricably linked to the temperature of the environment from which they draw heat. Thus, the higher the ambient temperature, the higher the efficiency achieved, and vice versa. For air-cooled pumps, this means that the climatic conditions of the area where the application is intended must be taken seriously into account in order to decide whether to be the sole source of heat generation or to be combined with an auxiliary energy source (boiler, auxiliary resistors, etc.), and to ensure that the system works with the highest possible energy benefit. For geothermal pumps things are different, since the temperatures of the subsoil, with which they exchange heat, from the first couple of meters are kept almost constant throughout the year. They thus take advantage of the accumulated energy load, due to the continuous solar radiation, which is found in the first layers of geological formations and in underground or surface aquifers, achieving higher seasonal efficiencies.

Inversely proportional is the relationship between the efficiency of the pumps and the supply temperatures to the distribution network. The higher the desired temperature, the lower the efficiency. This is the only reason why it is recommended to combine heat pumps with low temperature systems, such as floor-wall-ceiling surface heating and fancoils. Of course, the use of radiators is not prohibitive either, provided they are sized for operation at low water temperatures. Of course, also in heat pump technology, the logic of progressive operation with the use of compensation automation is essential if maximum energy benefits are to be achieved.

According to the Ecodesign Directive and the Energy Label, the highest scale in which heat pumps can be classified, without the use of automation, is A++.

Condensing technology boilers

Condensing boilers are now the only solution to the use of fossil fuels. However, with the use of high water temperatures they are treated in installations to a significant extent as common boilers, essentially missing out on many of the advantages offered by this technology.

To understand these advantages we must first understand how condensing boilers work. In practice, what condensing boilers do is to use the energy (latent heat) stored in the exhaust gas vapour (which is derived from the hydrogen in the fuel and the moisture in the fuel and combustion air) that in a conventional boiler would be released into the environment. This is achieved by using special exchangers (stainless steel or aluminium-silicon) before the exhaust gases are discharged to the environment, where the return water from the installation removes this energy and returns it to the heating system, the natural effect being the cooling and condensation of the water vapour. At the same time, the flue gas temperature is reduced to a significant degree, about 10˚C above the boiler water temperature, even reaching levels of 45-50˚C (instead of 180-200˚C compared to a conventional boiler). Through this process of recovery of latent energy, an increase in boiler efficiency is also achieved, where from 93%, which is the highest with conventional combustion technology, it can under certain conditions even reach 108%, always referring to the lower calorific value of the fuel.What is not usually taken into account is that condensing technology starts to be exploited when the exhaust gas temperature falls to approximately below 57˚C for gas and about 47˚C for oil. This practically means boiler inlet temperatures to the installation that will not exceed 65˚C.

It is immediately apparent that the lower the water inlet temperatures we work with the condensing boiler, the more energy is recovered from the flue gases, reaching the maximum possible efficiency of 108% and the lowest possible fuel consumption. Thus, the combination of condensing boilers with low temperature systems such as floor, wall and ceiling heating and local fan coil water conditioning units with a temperature range of 35-50˚C is ideal, achieving standard efficiency levels. Combination with radiators can be made equally efficient, as if one chooses to work with water inlet temperatures of 70˚C maximum one already achieves a better degree of efficiency than a conventional boiler, and if one chooses to size the radiators for efficiencies with lower temperatures in the range of 50-55˚C one achieves even better results. The positive thing is that in Greece, for reasons not relevant to this article, we find a large percentage of oversized radiators, making it possible to replace the old boiler with a new technology, without the need for large-scale and costly interventions.

However, a prerequisite for these systems is the combination of the condensing boiler with automatic compensation for progressive operation of the heating system, where the water supply temperature varies continuously according to the external temperature, where in periods with partial heating loads it is possible to use low temperatures.

In addition, condensing boilers mostly have a premixed combustion system (the combustion air is mixed with the fuel before entering the combustion chamber) and electronically controlled variable-speed fans, thus coming very close to the theoretical model of perfect combustion over the entire boiler power range, which means that the emission of 'dangerous' pollutants such as CO (carbon monoxide) and NOx (nitrogen oxides) is minimised to the maximum. Thus condensing boilers are not only economical in terms of fuel consumption, but also very environmentally friendly.

Finally, a very important advantage offered by condensing technology is the possibility of replacing a high-power boiler in larger buildings with an array of several boilers together of smaller capacity each, in parallel hydraulic arrangement. Since in larger scale applications, the power required to meet thermal needs varies significantly during the winter season, and is a function of both the variation in outdoor temperatures and the timing of loads, the condensing boiler array comes to provide high energy efficiency solutions. Thus, the number of boilers and the power percentage of each boiler selected by the central automation system controlling the array is a function of the actual load demanded. The advantages of the condensing boiler array are numerous and significant, as:

a) we make maximum use of condensation technology,

b) we achieve full analog operation with a power setting of 1:7,

c) achieve maximum savings in fuel consumption; and

d) we have total flexibility with the possibility of future expansion of the system.

Ventilation with heat recovery

The interiors of a building, whether it is a domestic or commercial application, are bound to need ventilation and renewal of the "dirty" air with fresh air from the outside environment. Particularly in new construction where the spaces are airtight this need is even more imperative. However, in conventional ventilation systems what happens is that conditioned air is simply expelled to the outside environment, and new unconditioned air enters the building. Practically whatever energy we have spent to heat or cool the internal air of the building is simply being rejected into the environment, "throwing money out the window".

The interiors of a building, whether it is a domestic or commercial application, are bound to need ventilation and renewal of the "dirty" air with fresh air from the outside environment. Particularly in new construction where the spaces are airtight this need is even more imperative. However, in conventional ventilation systems what happens is that conditioned air is simply expelled to the outside environment, and new unconditioned air enters the building. Practically whatever energy we have spent to heat or cool the internal air of the building is simply being rejected into the environment, "throwing money out the window".

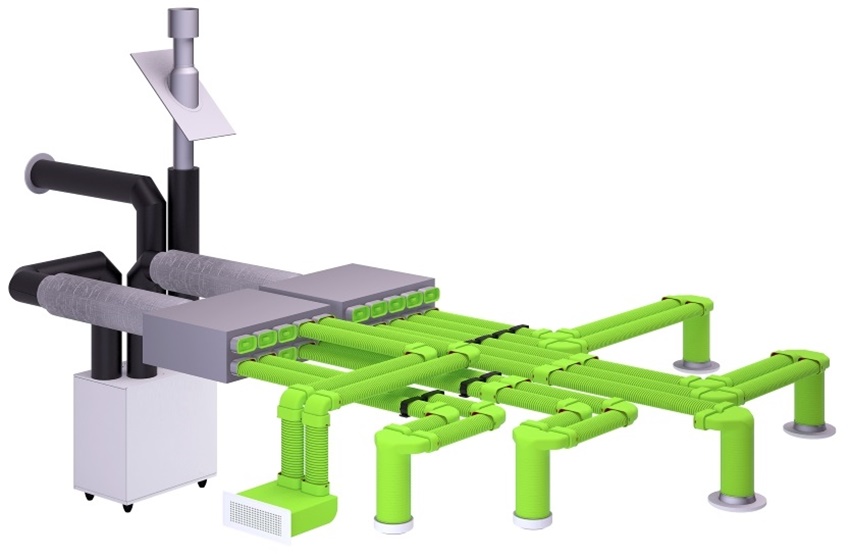

Heat recovery ventilation systems do not provide us with extra energy, but help us to renew the indoor air while preserving the energy of the indoor space. A heat recovery ventilation unit consists of two high energy efficiency fans, a special air-to-air exchanger, a fresh air filter and of course a controller. The system extracts air and humidity from the utility rooms (kitchen, bathroom, etc.) through a network of air ducts and after passing through the special exchanger it is discharged into the environment. At the same time, fresh air enters the exchanger through a parallel network of air ducts after being filtered, crossed without coming into contact with the "dirty" air, recovers part of its energy and enters the indoor spaces (living rooms, etc.) pre-conditioned. Indirectly through openings the fresh pre-conditioned air will also reach the ancillary rooms. Mechanical ventilation systems with recovery have the ability to regulate the air temperature, and many can also regulate the humidity through suitable switches. They also have a bypass system where fresh cool air is allowed in during the summer period, at times when the outside temperature is lower than the inside temperature (morning or evening).

Modern ventilation recovery systems achieve efficiency levels of up to 90%, making them the most reliable energy proposal for providing fresh air in buildings, free of dust, exhaust gases, pollen and humidity, while the results are particularly important in areas where people with respiratory problems, allergies and asthma reside.

Automations

The installation of automation and central energy management controllers for heating and air conditioning systems are complementary rather than a single intervention, where in combination with the rest of the equipment they contribute to the maximum energy savings of a building. In addition, automation upgrades the energy identity of a heating system to the highest possible class.

Depending on the size and type of application, there are a variety of automation solutions available on the market, some of the main ones being the following:

- Smart electronic room thermostats, with high and reduced heating period schedules, remote control via WiFi, very low temperature deviation between desired and measured, which even have a self-training program based on the recorded history of each room.

- Heating compensation controllers based on external temperature using a sensor for the control of mixing valves in combination with existing low temperature boilers of conventional technology or for direct combination with condensing boilers.

- Central building control system (B.M.S.), which is the most comprehensive energy efficiency system. Thus the building is controlled as a whole, providing additional energy reports with detailed visualization, recording and management of the installation either locally or remotely, offering the user excellent comfort levels and maximum energy savings.

Practical energy-saving tips

- Maintaining a constant temperature in the room:

Fuel consumption is directly related to the required temperature in the rooms. According to standards the acceptable indoor temperature should be 20˚C, and for each degree above this temperature the increase in fuel consumption is in the order of 6-7%. Choosing a constant temperature throughout the day with small temperature deviations when the premises are not occupied can result in significant savings. The installation of a modern electronic thermostat with a time-programmed automatic transition from the high temperature period to the low temperature period can help in this direction.

- Replacement of conventional circulators with new electronic high energy efficiency circulators:

The majority of heating installations have old technology circulators with low energy efficiency and high power consumption. Unfortunately, circulators are the part of the heating distribution network that we only realise is there when it breaks down. However, it is the product that has the most operating hours (average 2000 hours per year) and is a "hidden" consumption with high operating costs. Replacing old circulators with new Inverter technology, where according to the EU Ecodesign Directive they must have an EEI of less than 0.23, can reduce energy consumption by up to 80%.

- Installation of thermostatic valves and thermostatic heads:

Since each room of a building is completely separate with different thermal requirements, the solution is thermostatic heads. They are placed locally on each individual radiator and progressively adjust the flow of hot water based on the temperature of the specific room. In this way, each radiator becomes independent and is automatically isolated when the desired temperature is reached, while the other rooms requiring heating continue to operate. Thus when the building comes to thermal equilibrium a smaller part of the overall system will be operating, achieving fuel savings of up to 30%.

- Avoiding over-dimensioning of systems as the only result is overconsumption of fuel. Heating systems are designed to meet the worst climatic condition of the specific application. So even in the case where the heating design has been done ideally, taking into account all the necessary specifications, without any oversizing, 100% of the system power is required only for a very short period of time in winter, while the rest of the time is already more than needed. It is therefore easy to understand how much more burdened the consumption is with unnecessary over-dimensioning of the systems.

- Thermal insulation of pipes: Sounds perhaps the simplest procedure but nevertheless remains the least preferred. The thermal insulation of all visible piping of a distribution network in the heating system, in addition to being low cost and easy to install, will additionally contribute to energy savings and reduce consumption. Otherwise we produce energy (and of course spend money) to "throw it away" into the environment!

- Correct placement of room thermostats in places that are not affected by openings and thus lead the heating system to incorrect operation and overconsumption.

- Regular inspection and maintenance: The systematic monitoring of the operation of an installation in order to ensure its rational use and the timely prevention of potential problems contributes significantly to avoiding fuel overconsumption.

* Article by U.H.H.E. - Union of Hellenic Heating - Energy Enterprises